Trident delivers reliable, uninterrupted medical device manufacturing that meets exact specifications—every time.

Our advantage comes from combining Lean automotive manufacturing discipline with best-in-class medical device compliance, applied across the entire life cycle of your product.

The result:

Exceptional quality. Lower total cost. Faster delivery.

Manufacturing Built for Zero Tolerance

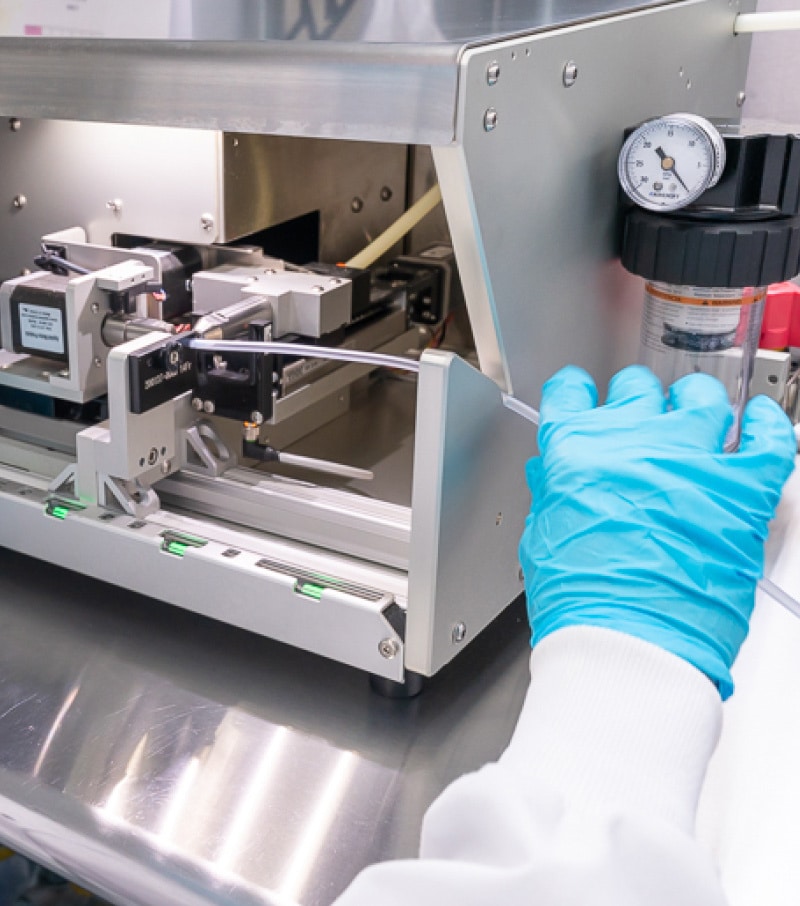

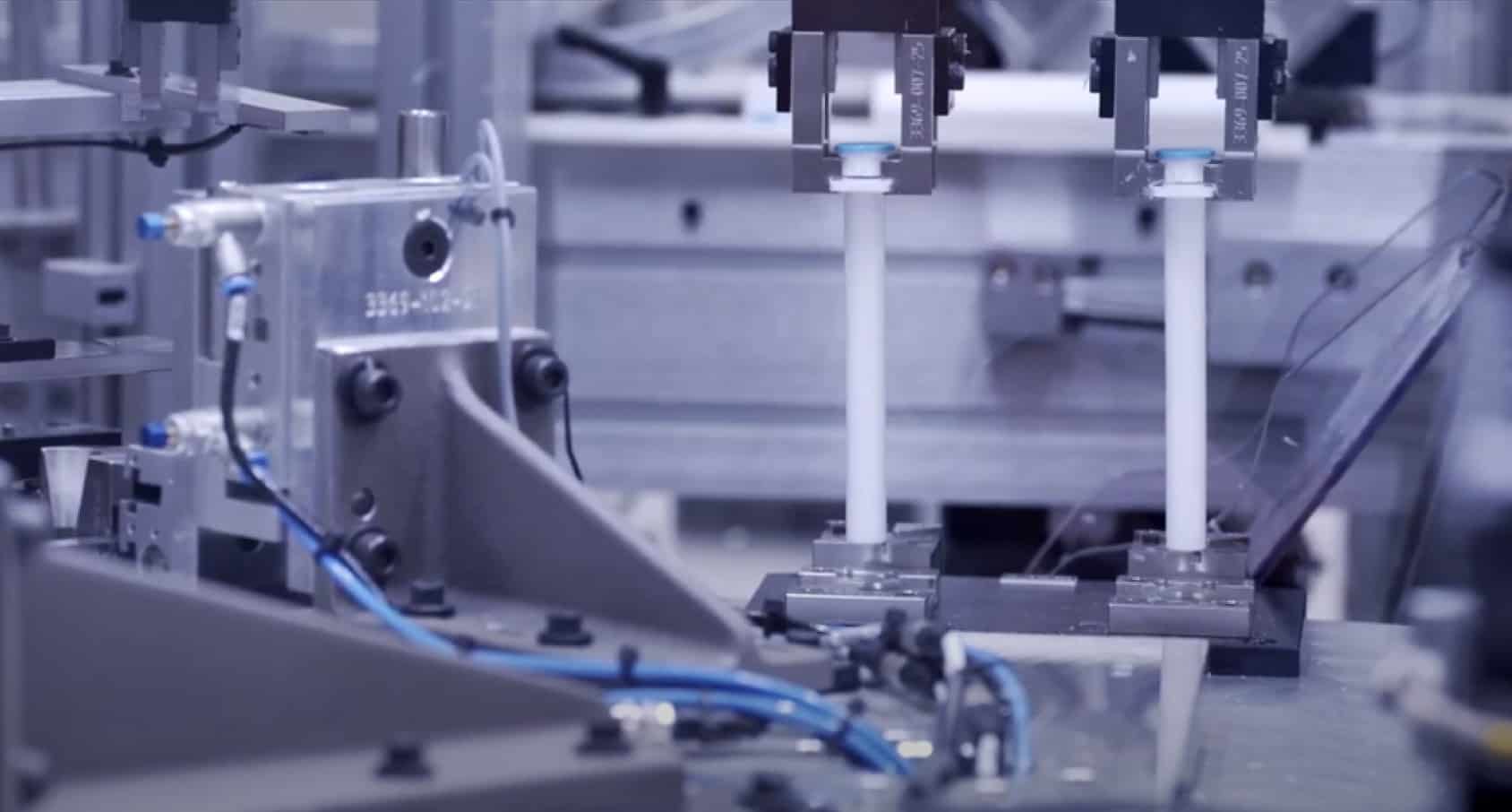

Trident operates in environments where precision, compliance, and consistency are non-negotiable.

Our capabilities include:

ISO 13485 certification

Turnkey Medical Device Manufacturing

We serve as a true end-to-end contract manufacturing partner for sterile and non-sterile Class I and Class II medical devices, including mechanical and electro-mechanical products.

You design the device. We deliver the finished, packaged product.

Core Capabilities

Design & Development

- Product design support

- Medical device design optimization and DFM

- Rapid prototyping and 3D printing

- Design and production validation

Manufacturing & Assembly

- Component manufacturing

- Strategic supply chain management

- Class 7 cleanroom or general assembly

- Complete device contract manufacturing

Advanced Assembly Processes

- Plastic welding (ultrasonic, vibration, heat staking)

- Adhesive bonding

- Electronics integration

- Suture management

- Needle and catheter assembly

- Potting, welding, and crimping

- Catheter tipping, drilling, and printing

- Tube sets and solvent bonding

- Pad printing and laser marking

- Filtration, foam, and media assembly

Testing, Packaging & Sterilization

- Functional and process testing

- Device, multi-pack, and master carton packaging

- UDI-serialized packaging capabilities

- Sterilization management

Why It Works

Whether you need full contract manufacturing or a scalable production partner, Trident is ready to deliver.

Better devices. Built smarter. Delivered ready.